Last month we began to talk about how tank-style storage water heaters have evolved into the devices we see today, and we’ll continue that here. We started by looking at the expansion tanks that are required on any closed water system, because there is so much interest in those little tanks and why they are needed.

However, historically the first main improvement that occurred due to all the explosions in storage water heaters was the addition of a safety valve that would ‘pop-off’ and relieve pressure buildup whenever there was too much heat or too much pressure. It’s called a temperature/pressure relief valve, or a T&P valve.

Around 1875, manufacturing changed ‘big-time’ when industry became able to produce big rolled plates. That was the beginning of large pressure vessels, from locomotives to boilers to big tanks of all sizes, and many other industrial applications. One of the outcomes of this new technology was that between 1870 and 1910, about 10,000 major explosions occurred in North America (about one boiler explosion every 36 hours). And though the number of explosions dramatically dropped after 1910 due to new safety relief valves being invented and used, they did still occur, causing injury, loss of life, and astronomical financial losses that translate to over $21 billion in today’s dollars.

Additional help was soon to follow. In 1914 the American Society of Mechanical Engineers (ASME) created the ASME Boiler & Pressure Vessel Code (BPVC) that regulates the design and construction of boilers and pressure vessels. This Code mandated the addition of pressure and/or temperature relief valves and systems, with proper design documentation submitted and approved on all pressure vessels. After many generations of improvements and changes, we now have the good quality, properly designed and manufactured temperature and relief valves for our water heaters.

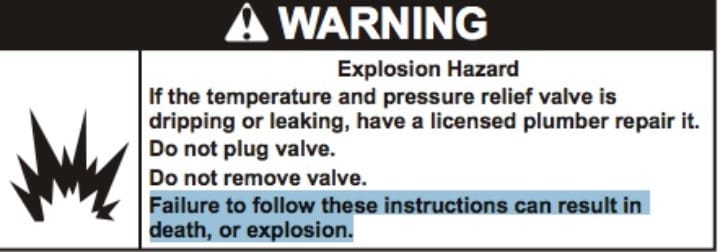

These safety devices are no less important today than in years past, and every once in a while, someone tries to cut corners or in ignorance caps a dripping T&P valve, and huge explosions often result. (If interested, a recent series called ‘Myth Busters’ did a little demonstration on water heaters exploding when safety is ignored. Now, all water heaters have this, or a similar warning posted on it by the manufacturer:

And as mentioned, all manufacturers require that annual safety inspections be done. That includes ‘tripping’ the little lever on the T&P valve to make sure it will open and to see that it will close without dripping. Homeowners and property managers who choose to skip this annual inspection just because it’s inconvenient when the T&P valves keep dripping and have to be replaced would do well to remember…

…just one example of thousands that have occurred when a water heater has a T&P valve not working properly.

Next month we’ll try to wrap things up and look at the other improvements that have evolved with the humble water heater.

Bruce Davis, Sr.

President, Director of Education and Learning, Sales Manager, Licensed Journeyman Plumber, Licensed Electrician,

HVAC/R Electrical Administrator, HVAC/R, Certified WA State C.E.U. Instructor

Bruce Sr is President of Day & Nite Plumbing & Heating, a 67-year-old family owned and operated plumbing and heating business in Lynnwood, Washington. Bruce can be contacted at: Email: Bruce@dayandnite.net

Day & Nite Plumbing & Heating Inc. 16614 13th Ave. W. Lynnwood, WA 98037 800-972-7000